In the drive towards innovation and efficiency in China's manufacturing sector, Shandong Hongcan Material Technology Co., Ltd., a subsidiary of China Hongqiao Group, has emerged as a pioneering force, revolutionizing the production of automotive aluminum alloy structural parts.

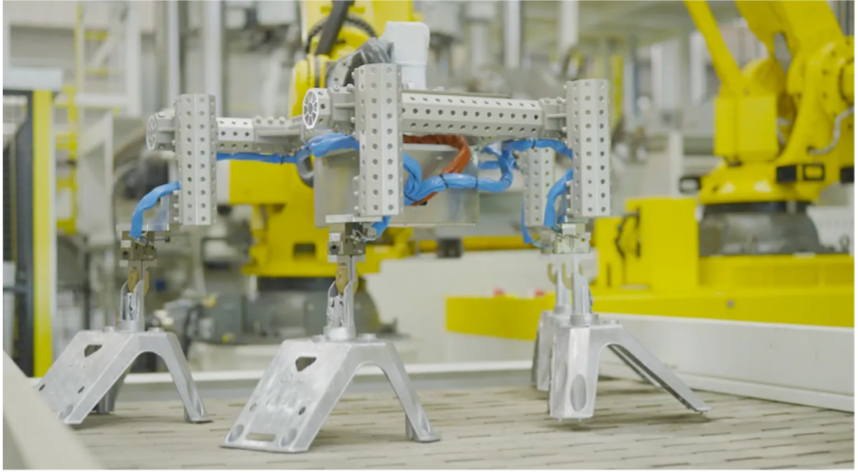

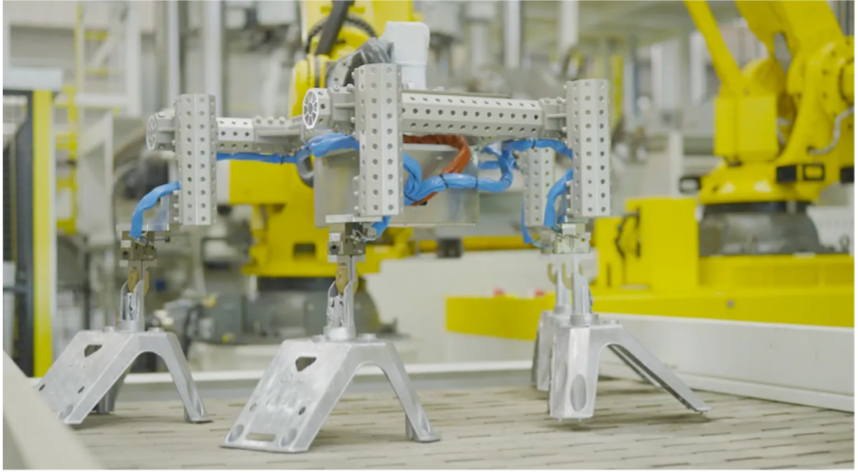

Recently, Shandong Hongcan Material Technology achieved a remarkable milestone by introducing China's first "One Mold Four Outputs" process. This groundbreaking technology allows a single mold to produce four automotive parts simultaneously, significantly enhancing production efficiency and reducing manufacturing costs. By streamlining production and reducing cycle times, this cutting-edge technique is poised to transform the automotive manufacturing landscape in China. Faced with technical challenges such as forming accuracy, internal quality control, and deformation prevention in the "one mold, four outputs" process, our Shandong Hongcan team ensured the perfect forming of the product and passed strict third-party tests, including mechanical performance, salt spray corrosion resistance, and collision safety verification.

This was made possible by our superb mold temperature control technology, precision nozzle system, high-quality aluminum liquid, and exquisite tooling design, supported by our experienced team of engineers. Overall, through a total investment of 1.7 billion yuan, our state-of-the-art facility at Shandong Hongcan Material Technology has been equipped with advanced equipment, including the world's most advanced Bühler die-casting machines essential for the “One Mold Four Outputs” process. The implementation of this innovative technology has marked a significant leap forward, enabling us to reduce production times from over 120 minutes to just 140 seconds. Additionally, it has resulted in an energy consumption reduction of over 10% per ton of product, while the material recycling rate has soared to over 95%.

By utilizing aluminum from upstream resources within the China Hongqiao Group, we have established the country's first "liquid aluminum-die casting-automobile manufacturing-recycling" green and environmentally friendly resource recycling demonstration industrial chain. Our main products include integrated die-casting aluminum alloy structural parts such as shock absorber towers, longitudinal beams, rear bottom plates, battery shells, and gearbox housings. With an annual production capacity of 3 million precision aluminum alloy structural parts across eight product categories, our subsidiary is set to play a pivotal role in supplying major automotive manufacturers, including Tesla, BYD, CATL, Chery Automobile, and BAIC Group.

Shandong Hongcan Material Technology's groundbreaking achievement exemplifies China Hongqiao’s ongoing commitment to innovation, sustainability, and the advancement of the manufacturing industry in China. Through continuous technological innovation and strategic investment, we are driving progress, promoting sustainable development, and shaping the future of manufacturing in China and beyond.

Sources: 魏桥创业 Weiqiao Pioneering Group Official WeChat Account

https://mp.weixin.qq.com/s/L-0I0FRyaDrjPr8DXXNpLg