On July 5, Shandong Hongtuo Industrial Co., Ltd. has been selected as a "leader" in energy efficiency in key industries for 2023 by the Ministry of Industry and Information Technology, the National Development and Reform Commission, and the State Administration for Market Regulation.

This prestigious recognition underscores our commitment to sustainability and energy efficiency. Our inclusion in the list of energy efficiency "leaders" shows we are on the right path to enhance energy utilization efficiency, reduce carbon emissions, and set benchmarks for industry standards.

The selection process, guided by the "Notice on Organizing the Selection of Energy Efficiency 'Leaders' Enterprises in Key Industries in 2023," involved local recommendations, expert reviews, and public announcements, ensuring that only the most example companies were chosen.

Innovative Measures and Outstanding Results

Shandong Hongtuo Industrial Co., Ltd. has made significant strides in energy efficiency, particularly in our alumina production using the Bayer process. Our unit product energy consumption stands at 300.78 kg of standard coal per ton, an impressive 11.54% improvement over the national advanced standard.

These are the key measures contributing to this achievement:

1. Closed Tubular Belt Conveyor System Project: Leveraging our plant's proximity to the port, we constructed a closed tubular belt conveyor system to replace traditional automobile transportation. This project has enabled the annual transport of 5.9398 million tons of ore, saving 2,646 tons of standard coal and reducing carbon dioxide emissions by 5,557 tons.

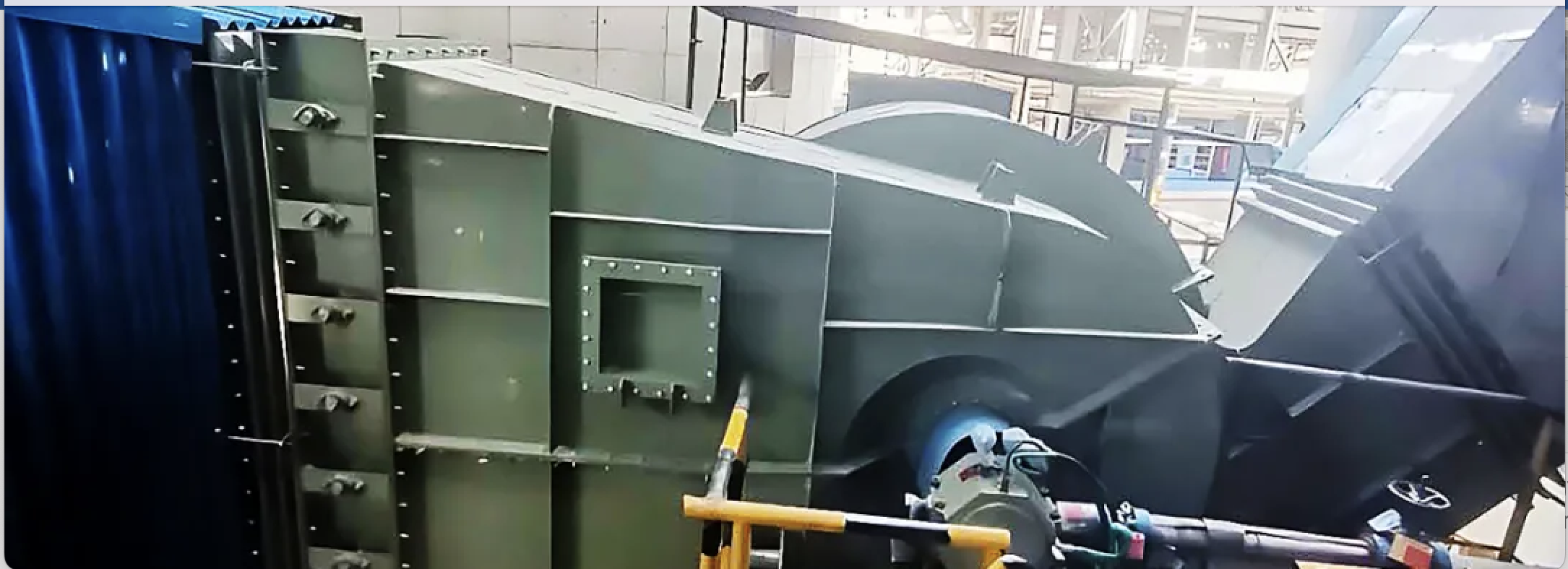

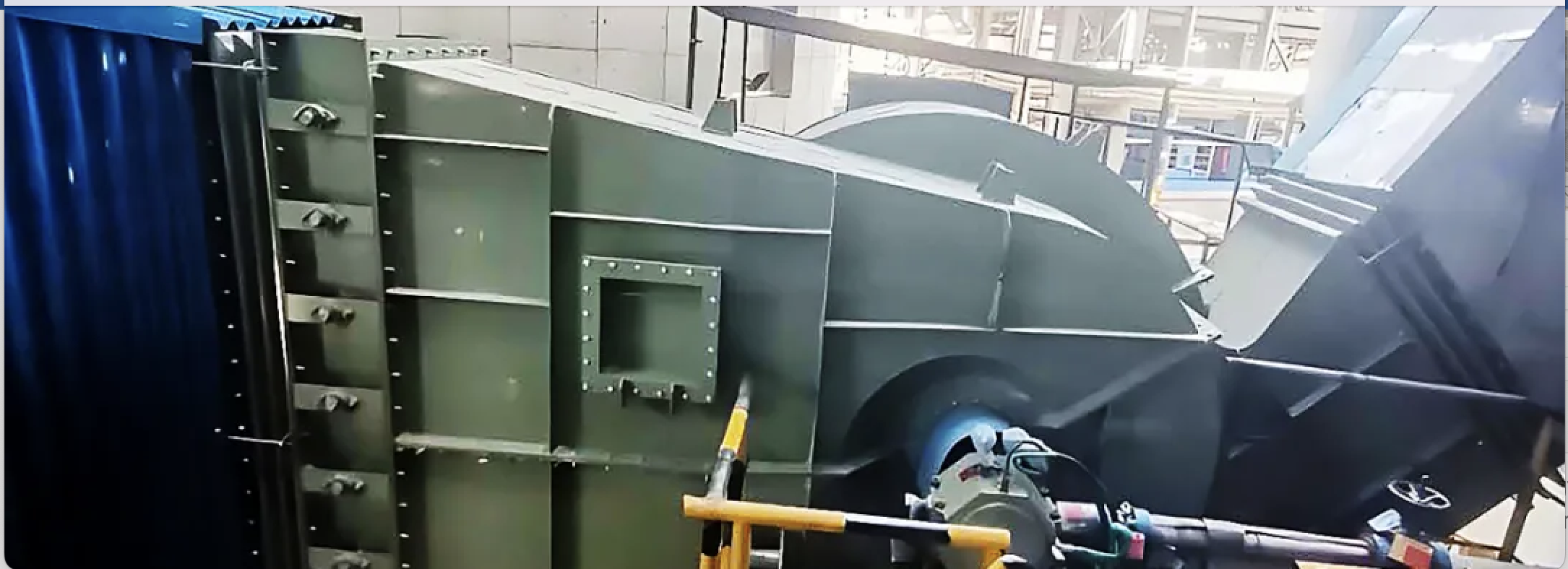

2. Upgrading Fans and Pumps: We have upgraded our fans and pumps by installing magnetic levitation vacuum pumps and energy-saving fans, replacing high-power equipment. This initiative saves 737 tons of standard coal annually.

3. Adopting New Energy Vehicles: Transitioning to new energy vehicles for transporting finished alumina to downstream enterprises has significantly reduced our reliance on diesel vehicles. This shift has resulted in 290,000 trips per year, saving 12,607 tons of standard coal and cutting carbon dioxide emissions by 26,476 tons.

4. Establishing an Energy Centralized Control Management Center : We have integrated the DCS system units of each process to create a centralized control management center. This system facilitates energy monitoring, consumption statistics, analysis, cost assessment, and lays the groundwork for energy consumption feedforward control and optimized scheduling.

A Commitment to Sustainable Practices

Being recognized as an energy efficiency leader is a testament to Shandong Hongtuo Industrial Co., Ltd.'s dedication to sustainable practices and innovative solutions. We remain committed to driving forward the industry's standards, continually improving our processes, and reducing our environmental impact.

As we celebrate this achievement, we look forward to continuing our journey towards greater energy efficiency and sustainability, setting new benchmarks, and leading by example in the industrial sector.

Source: Weiqiao Pioneering Wechat OA (Original Content in Chinese)