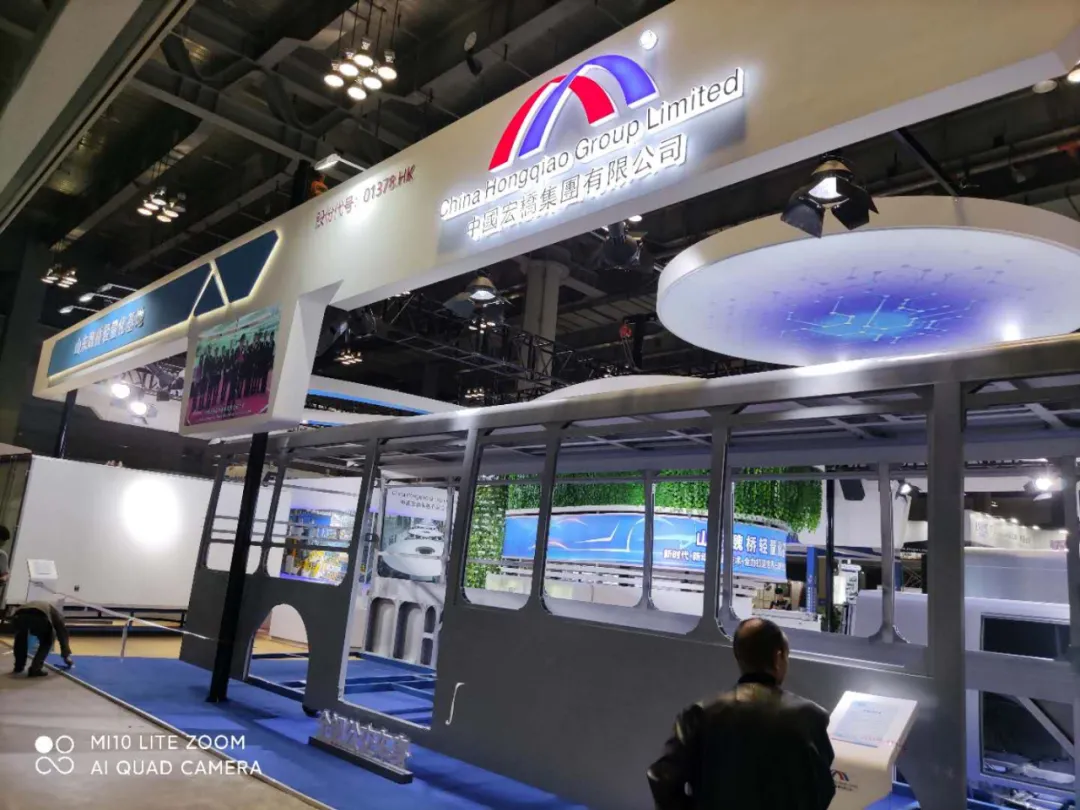

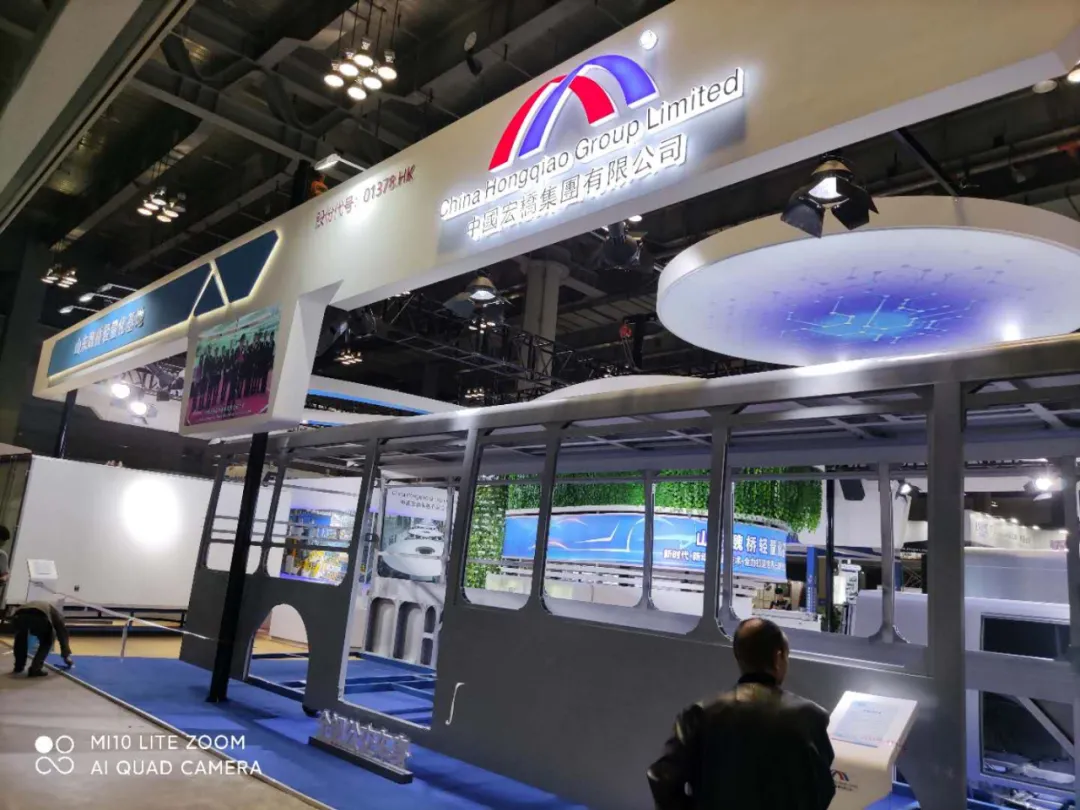

With the presence of our Chairman & Ceo, Mr. Zhang Bo, we exhibited both our most

popular products and also our latest automobile industry developed ones such as

all-aluminum bodies, all-aluminum chassis, and all-aluminum cargo boxes

independently developed which were very well received by the industry

professionals from automobile manufacturers and research institutes.

The all-aluminum bus body

displayed in the exhibition uses a new high-performance aluminum alloy

extrusion casting connector, which is connected by bolt cold connection, with

high dimensional accuracy, torsional rigidity up to 25000N/mm, and the five

major body frame reducing the weight of the traditional steel body by about

45%.

The all-aluminum body

sub-assembly adopts cold metal transition welding (CMT), which effectively guarantees the mechanical

properties and stability, with torsional stiffness as high as 10000N/mm.

The all-aluminum chassis

platform adopts world-class advanced SPF/FDS with a body that is 40% lighter

than traditional steel body but maintains the overall rigidity and strength at

a weight of only 140kg. This flexible design is suitable for for A-class and

B-class passenger models.

China Hongqiao is committed

to building the most advanced and full-process automotive lightweight research

and development, testing and manufacturing base in China to be able to expand

to the research and development of lightweight components in the fields of rail

transit, aerospace, military, marine engineering, etc. At present, a

complete R&D system and scientific research team has been established, with

more than 200 R&D personnel and more than 20 top lightweight experts from China

and abroad.